Client:

Hemspan Ltd

Location:

Rochford, Essex

Project:

Rochford Park Factory Planning Business Case

Timeline:

2024 - 2025

Value: Confidential

Service: Business Planning and Process Design

Project Description

To support the delivery of the Rochford Park Masterplan, a new 2,000 dwelling climate-positive community in Essex, our client HEMSPAN®, will establish a strategy and business case for a vertically integrated dedicated manufacturing facility.

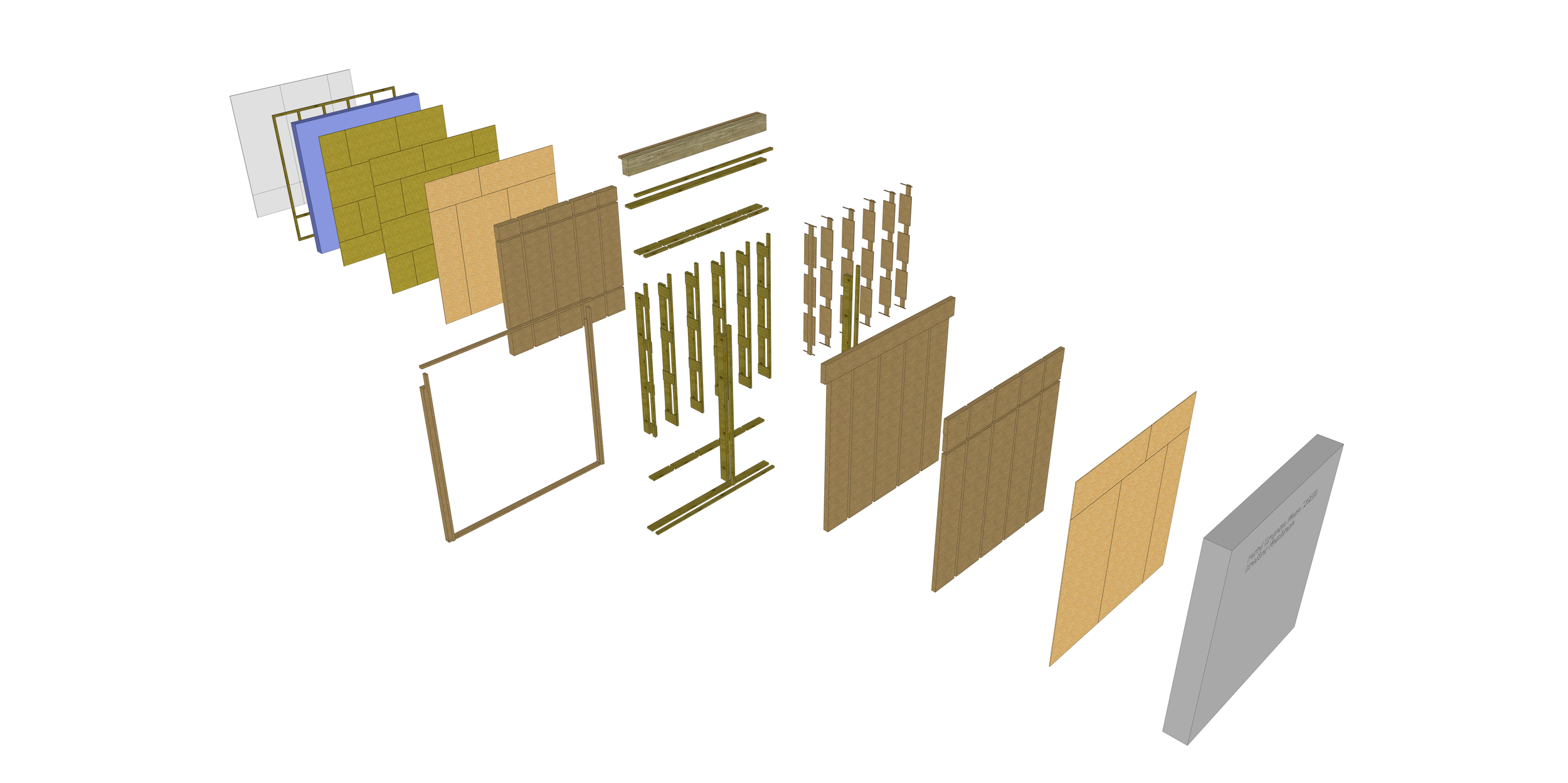

The vision to develop the factory, will enable HEMSPAN® to become the sole producer of the BIOHAUS® 2D closed panel building system (See BIOHAUS® case study), ensuring consistent quality and high performance across all the homes in Rochford Park, as well as serve as a central hub to produce BIOHAUS® for use in other developments nationwide.

Description of our Work

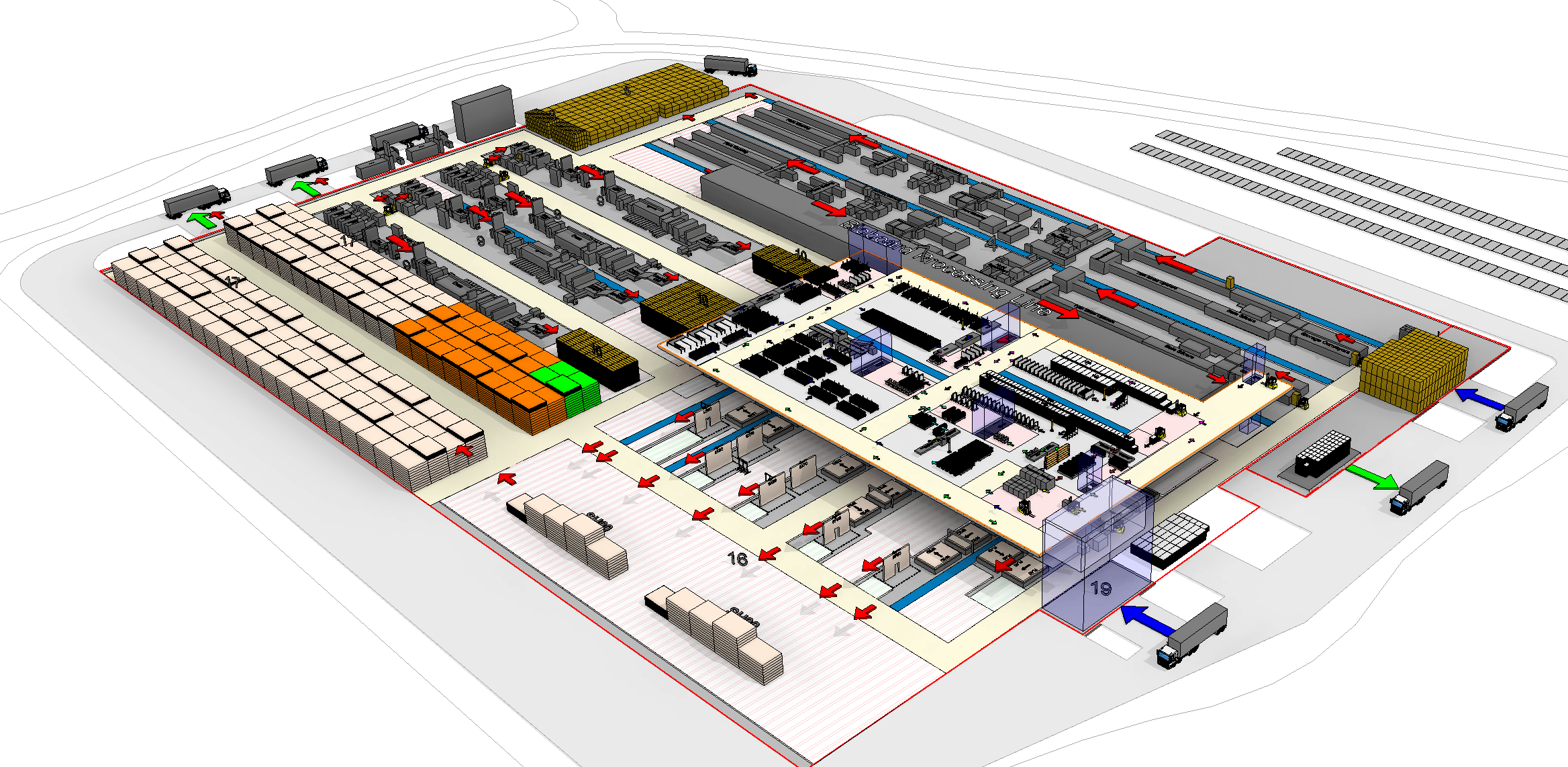

APPLY developed a factory process plan and business case for the BIOHAUS® Manufacturing Facility to support an outline planning application.

The proposed facility occupies approximately 48,000m², comprising a 42,000m² ground floor manufacturing hall and a 6,000m² mezzanine level for material preparation and sub-assembly. It is designed to produce 2,000 homes per year, creating around 350 local jobs, with an additional 175 indirect employment opportunities.

This vertically integrated factory will process 24 tonnes of locally grown hemp per hour, supplying raw materials to produce HEMSPAN® insulation products and Bio Board for the BIOHAUS® Building System and external sales.

The 266m² West Swainsford farmhouse (See project page) served as the prototype for homes produced within the facility, informing panel quantities, optimal panel sizing, and material requirements. This data established the foundation for defining the manufacturing process to meet the annual production target, including the decortication zone, Bio Board processing zone, Airlay processing zone, framing assembly zone, and mezzanine-level sub-assembly and preparation areas.

Using Revit, these zones were modelled to analyse manufacturing flow and takt time, material delivery and storage points, safe and efficient movement routes for vehicles and personnel, finished goods storage, and loading bay arrangements.

The strategy informs a comprehensive business case outlining the key parameters for the panel manufacturing facility detailing the factory layout, activities at each production station, output capacity, workforce requirements, and financial projections for one start-up and five operating years, with provision for scalable production growth over time.

APPLY Structure Ltd is a proud partner and investor in Hemspan Ltd.