Client:

Hemspan Ltd

Location:

Mere, Wiltshire

Project:

Private House - West Swansford Farm

Timeline:

2024 - Ongoing

Value:

Confidential

Project Design Team:

ADEPT Consulting, Carbon Free Group, Eight Versa, Gracelands, TImber Innovations

Project Description

Having supported HEMSPAN® with the technical development of BIOHAUS® (see case study), this project for a modest Wiltshire farmhouse, aims to demonstrate the application of passive house principles to the delivery of a high performing building with a contextual aesthetic.

HEMSPAN® is a construction technology business developing bio-based, circular systems to capture and store atmospheric carbon in buildings. BIOHAUS® is a BOPAS-accredited (see case study), high-performance, whole-house Category 2 closed panel system setting the benchmark for climate positive living. BIOHAUS® provides a structural solution for residential and public buildings up to three storeys, with further scope to develop designs for buildings up to 18 metres (five storeys).

Description of our Work

APPLY led with a Design for Manufacture & Assembly (DfMA) approach for this traditional farmhouse design to be manufactured offsite and efficiently assembled on site. Optimising panel sizing, assembly methodology and interface details, (including air tightness) ensures panels can be manufactured, installed, and connected quickly, simply, and safely. The multidisciplinary team provided production information to RIBA Stage 4 including architectural and structural engineering, thermal modelling, and MEP design services within this DfMA framework.

The client brief required an efficiency that sets the standard for further projects, with viable sustainable qualities, and superior performance. The initial predicted energy assessment uses government approved SAP10 methodology and is rated in terms of energy use per m2 of floor area. The energy efficiency is based on fuel costs and the environmental impact based on carbo dioxide (CO) emissions.

The fabric-first approach to the design of the BIOHAUS® system, combined with advanced monitoring technology, provides precise real-time performance data to optimise thermal comfort and reduce energy use through integrated renewable technologies. This pilot project serves as a demonstration of a carbon-negative, energy-efficient building system that is delivering towards the UK’s net zero goals.

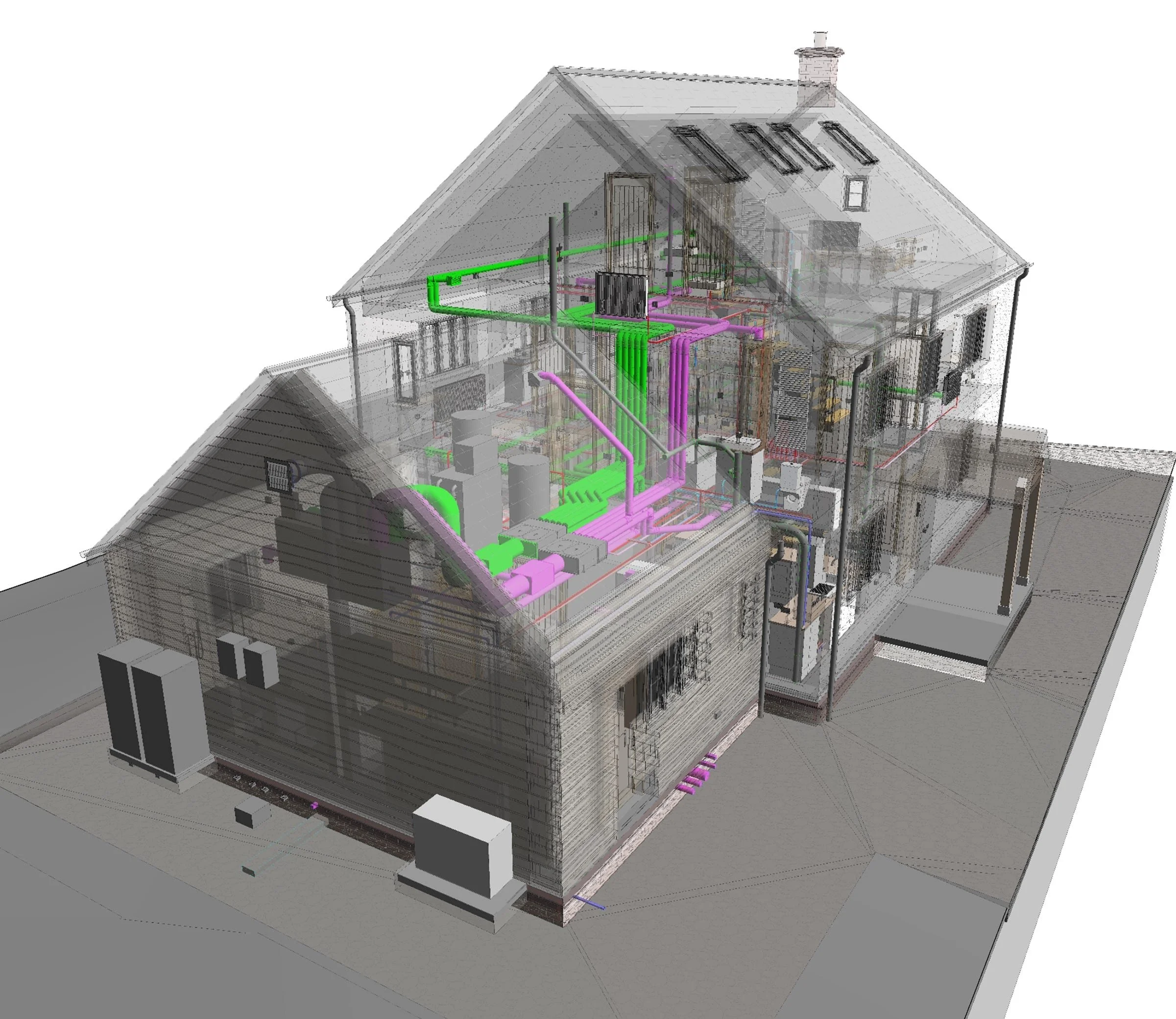

By employing Revit and BIM protocols the development of the architectural, structural, thermal, MEP, and manufacturing information was fully coordinated through the design and manufacturing process, together with the high performing on site foundation works. APPLY led the design team and developed the final federated model to support clash detection and coordination well in advance of manufacture and construction.

APPLY and Hemspan selected Autodesk Construction Cloud (ACC) to coordinate the design, manufacturing, construction, and operation workflows for all BIOHAUS® projects. It provides tools for document management, design collaboration, project planning, preconstruction, construction execution, and project closeout, improving communication, efficiency, quality, and profitability across the entire project lifecycle.

APPLY Structure Ltd is a proud partner and investor in Hemspan Ltd.